Chemical Hazards in Georgia Food Processing Plants

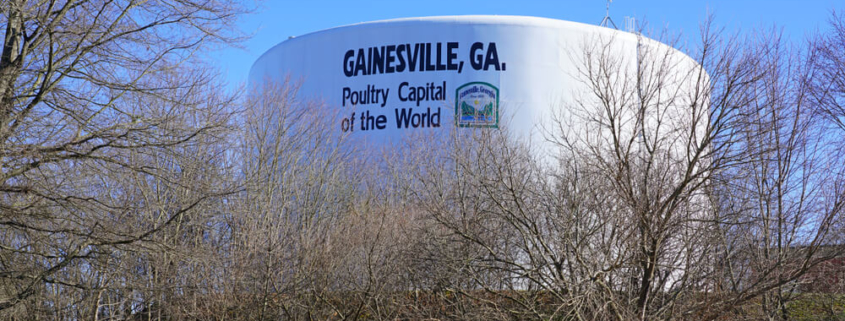

Late last week, six food plant workers were killed and several others were injured because of a liquid nitrogen leak at a Gainesville, GA poultry plant. Poultry plants rely heavily on the use of refrigeration systems to keep the food fresh, and many of the systems contain liquid nitrogen. The cause of the leak is not yet known and currently under investigation. Our hearts go out to the victims and their families, none of whom could have foreseen the tragic events that unfolded that day.

Food Processing Plant Workers Deemed Essential During COVID-19

The food processing industry is critical to our way of life. We realized this more than ever last year as the COVID-19 pandemic swept through our nation. With our meat supply chain threatened, President Trump issued an executive order for meat and poultry plants to re-open – even though many of their workers had contracted the coronavirus.

At the peak of the COVID-19 outbreak, there was a lot of focus on implementing measures to prevent the spread of infectious diseases in food processing plants. Among these included the use of gloves, gowns, face masks, and face shields, as well as plexiglass barriers and a 6-foot distance between workstations. All of this and more is necessary and appropriate to protect these highly essential workers from getting the virus.

Chemical Hazards in Food Processing Plants

Although the threat of contracting COVID-19 is a huge concern in food processing plants, the spread of infectious diseases is not the only major hazard that workers in these plants are exposed to. As we saw with the liquid nitrogen leak that claimed the lives of six food plant workers last week, chemical safety is another top concern that is often overlooked.

According to a study by the University of Southern Indiana, there are approximately 750,000 hazardous chemicals that are used in the workplace, and hundreds more are added every year. In food processing and other types of manufacturing, chemicals are used for a wide variety of purposes. These include manufacturing and preserving food, cleaning and disinfecting surfaces, and as we talked about earlier, keeping the food refrigerated.

Poorly maintained refrigeration systems can result in releases of deadly chemicals like liquid nitrogen and ammonia, which can cause serious injuries and fatalities to workers in these facilities. Some of these chemicals are also highly flammable at various levels of concentration, which can lead to fires and explosions in manufacturing and processing plants.

Toxic chemicals can come in a number of forms and enter the body in a number of different ways:

- Dusts and particles may be inhaled or ingested.

- Liquid chemicals may be absorbed into the skin.

- Mists may be absorbed or inhaled.

- Gases and vapors, many of which are invisible, may be inhaled without the worker even realizing it.

The health hazards posed by toxic chemicals could either be acute or chronic. Acute hazards occur quickly after exposure, as was the case with the deadly liquid nitrogen leak at the Gainesville poultry plant. Chronic hazards are those that occur gradually after repeated exposures, which is more common with less toxic chemicals.

Measures to Reduce the Risk of Chemical Hazards in the Workplace

Chemical exposure is a safety hazard that affects workplaces across a wide range of industries. From food processing to other types of manufacturing and processing to construction to oil and gas, millions of workers in Georgia and throughout the country risk exposure to hazardous chemicals.

Because hazardous chemicals endanger the health of employees, there are a number of safety measures that employers should take to protect their workers:

- Personal Protective Equipment (PPE): Employees should be provided with the clothing and accessories needed to protect them from chemical exposure. This may include goggles, face shields, and chemical resistant gloves, footwear, and other clothing.

- Chemical Labeling and Safety Data Sheets: Companies that manufacture, distribute, and import chemicals are required to provide labels and safety data sheets with information about the identities and hazards of the chemicals that are produced and distributed.

- Hazard Communication: OSHA requires all employers that have hazardous chemicals in their workplaces to develop and implement a hazard communication program. This includes ensuring that all chemical containers are labeled properly, making safety data sheets available and understandable to workers, educating employees about the hazardous substances they are working with, and training them to handle the chemicals safely and appropriately.

- Machine Guarding: It is absolutely critical that machinery and equipment that contains hazardous chemicals be maintained regularly in order to prevent leaks and breakdowns like the liquid nitrogen leak that happened last week.

- Proper Material Handling and Storage: Handling, storing, and disposing of chemicals properly helps minimize the risk of toxic exposure, explosions, fires, and other workplace accidents. Regular inspections should also be conducted in areas where chemicals are stored to identify damaged containers and other possible signs of chemical leakage.

- Emergency Response: Emergency response procedures should be in place in the event that a worker suffers a chemical injury. For example, workers should be well-informed of the locations of available first-aid kits and eyewash stations, so they can get to them even with limited vision from chemical exposure to their eyes. In addition, any chemical spills that occur should be cleaned right away using the instructions provided by the product maker.

Legal Options for Workers Who are Exposed to Hazardous Chemicals

Chemical exposure in the workplace can result in serious injuries and fatalities. And when this happens, workers and their families deserve to be fully compensated. You may think that the only option after a workplace injury is to file a workers’ workers’ compensation claim. However, this is not always the case. Although you are generally not allowed to sue a Georgia employer if they provide workers’ comp coverage, it might be possible to file a civil claim against another liable party.

For example, if a worker is exposed to harmful chemicals because of defective machinery or mislabeling, you may be able to file a product liability claim against the manufacturer or distributor. Or another common instance is when a third-party subcontractor is working on site and causes a chemical spill, in which case you may be able to file a personal injury lawsuit against the subcontractor.

Cases like these can be very complicated, and there are typically multiple factors that may have contributed to a worker’s injury. A thorough investigation is required to get to the bottom of what happened and identify any and all contributing factors. And this is where we can help.

At Bailey, Javins & Carter, L.C., we have five decades of experience standing up for injured workers. Over the years, our lawyers have successfully handled some of the most complex workplace injury cases, and we have recovered millions of dollars in verdicts and settlements on behalf of our clients. We work closely with our clients, and we look beyond workers’ compensation to explore every potential legal avenue toward recovering maximum compensation.

If you or a loved one suffered a serious or fatal workplace injury because of chemical exposure or any other reason, we are ready to go to work for you! For a free consultation and case assessment with one of our attorneys, message us online or call our Atlanta office today at 678-981-5370.